Product category:Foods Vacuum Cooler

Material: 304 stainless steel

Applicable food: rice, noodles, pasta, bread, cooked food

Function: cool down cooked food rapidly in 7~20 minutes

Cooling type: air cooling

Email: sales@huaxianfresh.com nicowork@foxmail.com

Tel: +86-15920633487(Whatsapp/wechat)

Office: +86-769-81881339

Details description

120kgs Stainless Steel Pasta Noodles Vacuum Cooling Machine

Principle of vacuum precooling machine: Under a standard atmospheric pressure, the boiling point of water is 100 degrees Celsius, and the heat of evaporation is 2256.69KJ/kg; when the pressure is reduced to 613 Pa, the boiling point of water is 0 degrees Celsius, and the heat of evaporation is 2499.52KJ/kg. As the pressure decreases, the boiling point temperature of water also decreases, and the heat consumed in evaporating unit mass of water increases. The principle of vacuum cooling technology is to place high-temperature objects such as cooled fruits, vegetables, and cooked foods in a vacuum cooling chamber, and extract air through a vacuum pump to create a low-pressure environment, so that the moisture inside the product can evaporate; because the evaporation process is accompanied by heat absorption, Causes the temperature of the evaporated material itself to decrease.

Usage of vacuum cooler

The cooked food vacuum precooling machine is mainly used in food thermal processing enterprises such as aviation fast food, high-speed rail fast food, braised meat processing, chain restaurants, bread making, etc. A typical application in the food processing industry is the pre-cooling of cooked food. It takes a long time for the cooked food to cool naturally after cooking or making, which can easily lead to the loss of quality and color of the cooked food. The cooked food vacuum pre-cooling machine can cool down to normal temperature in a short time and then freeze it for storage, which greatly extends the shelf life and nutritional value of cooked food.

Why we need to cool food quickly?

Temperature is one of the most important parameters affecting food quality and safety. Within the temperature range, the lower the temperature, the slower the bacterial reproduction; the higher the temperature, the faster the bacterial reproduction (generally the suitable temperature for microbial growth is 28°C-37°C). Through rapid cooling, the cooling process of food materials is greatly shortened. The time within this dangerous temperature zone reduces the risk of bacterial reproduction and extends the shelf life.

Our advantage

Product advantages

u All stainless steel material to meet the high hygiene requirements of food.

u Energy-saving custom water trap, energy saving 40%, good cooling effect.

u Dual vacuum temperature control, no pollution, convenient operation.

u Vacuum pump never changes oil, easy to clean, no maintenance needed.

u Compact design, small footprint.

u All stainless steel, high-end beautiful.

u Multiple system protection and fault correction prompt function.

u Optional remote monitoring function, real-time understanding of machine operating conditions.

u Soup anti-splash function.

u More friendly man-machine interface, intelligent functions, multi-purpose.

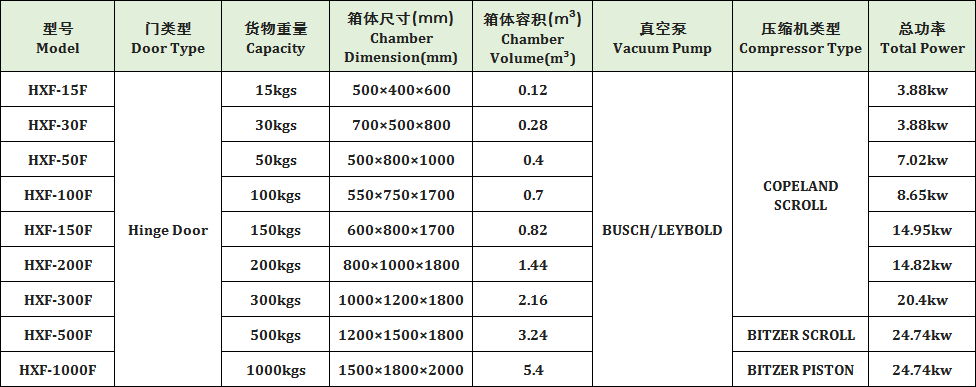

Model selection