Product category:Vacuum Freeze Dryer

20 m² Vacuum Freeze Dryer, 200kgs/batch, dry the vegetable, fruit, meat, fish, ginger without nutrition loss. It is healthy food drying way.

Email: sales@huaxianfresh.com nicowork@foxmail.com

Tel: +86-15920633487(Whatsapp/wechat)

Office: +86-769-81881339

Details description

20 m² (200kgs/batch) Vacuum Freeze Dryer

Freeze drying machine is a kind of low-temperature drying equipment that uses the principle of sublimation to dehydrate materials, also known as vacuum freeze dryer! The principle of freeze-drying machine is to freeze water-containing materials into solid, and use the sublimation performance of water under low temperature and low pressure to dehydrate the materials at low temperature to achieve a new drying method. The products obtained by vacuum freeze-drying are called freeze-dried products.

The principle of the freeze-drying machine is simple, that is to put the sample in a vacuum environment. Through the process from high temperature to low temperature, the free water in the sample will volatilize, and the bound water in the sample will not volatilize. The purpose is to increase the storage time of the sample.

Water has three phases: solid, liquid and gas. According to the theory of phase equilibrium in thermodynamics, with the decrease of pressure, the freezing point of water changes little, but the boiling point is getting lower and lower. When the pressure drops to a certain degree of vacuum, the boiling point of water coincides with the freezing point, and ice can be directly vaporized into gas without liquid. This process is called sublimation. The vacuum freeze-drying of food is below the three-phase point of water, that is, under the condition of low temperature and low pressure, the frozen water in food is sublimated and removed.

Because the freeze-drying technology is carried out in low temperature and low oxygen environment, most of the biological reactions are stagnant, and there is no liquid water in the treatment process. The water sublimates directly in the solid state, so that the original structure and shape of the material are protected to the greatest extent, and finally the high-quality dry products with both appearance and internal quality are obtained. At present, freeze-drying technology has been widely used in many fields, especially in food processing to obtain high-quality dehydrated food.

Freeze drying process:

Pretreatment

Different sources and applications of raw materials lead to different pretreatment methods. For example, the pretreatment of fruits is to select, clean and cut into pieces, vegetables need to be blanched, and instant porridge needs to be steamed and put on the plate.

Pre-freezing

After the raw material pretreatment, the pre freezing is usually carried out. This is because when there is more water in the material, if vacuum treatment is carried out directly, the dissolved gas will escape due to the decrease of external pressure, forming bubbles, which will lead to void in the inner and surface of raw materials, which will affect the sensory quality.

Quick-frozen

In order to solidify the moisture in the material, quick freezing is usually needed. The shorter the freezing time, the faster the material freezes, the smaller the internal crystal and the less the mechanical damage to the material cells. Therefore, it is necessary to choose the appropriate freezing speed according to the actual production.

Vacuum drying

Vacuum drying is usually divided into two stages: sublimation drying and desorption drying. Sublimation drying mainly aims at free water in materials; Desorption drying is mainly to remove the adsorbed water which is strongly combined with solid. The vacuum degree, temperature and thickness of tray directly affect the drying process and product quality.

Our advantage

Dongguan Huaxian Ltd.

Huaxian produces vegetable vacuum cooler, cold storage room, hydro cooler, ice machine, freezing dryer since 2008.

In 2018, we focused on worldwide fresh care market and Dongguan Huaxian Ltd. was registered. In the same year, we were happy to open an office in USA.

Huaxian is engaged in fresh care by refrigeration and providing best fresh care solutions on food, meat, seafood, fruit, begetable by HUAXIAN quality refrigeration equipment and sophisticated technology, so as to maximum prolong shelf life and keep original freshness to create beneficial market values. Presently, our main market is in China, America, Europe, South East Asia and Australia. Gradually more and more customers lay trust on us and choose us for cooperation.

Energy saving is our constant persue as it is related with customer's investment yield rate. Our design proposal is fully based on energy saving and consumption reducing.

Guarantee

a. All HUAXIAN ice systems delivered to customers are carefully examined and tested, with 72 hours trouble-free trial operation.

b. All HUAXIAN ice systems delivered are plug-in ready and well piped.

c. All HUAXIAN ice systems enjoy 12 MONTHS guarantee ever since B/L date.

Technical support

a. HUAXIAN provide full technical support and after equipment installation.

b. 7*24 hours phone assistance on technical support.

Failure Claim procedures

a. Detailed written failure description is required by fax or by mail, indicating the relevant equipment information and detailed description of failure.

b. Relevant pictures are required for failure confirmation.

c. HUAXIAN engineering and after-sales service team will check and form a diagnosis report.

d. Further trouble-shooting solutions will be offered to customers within 24 hours after receiving the written description and pictures.

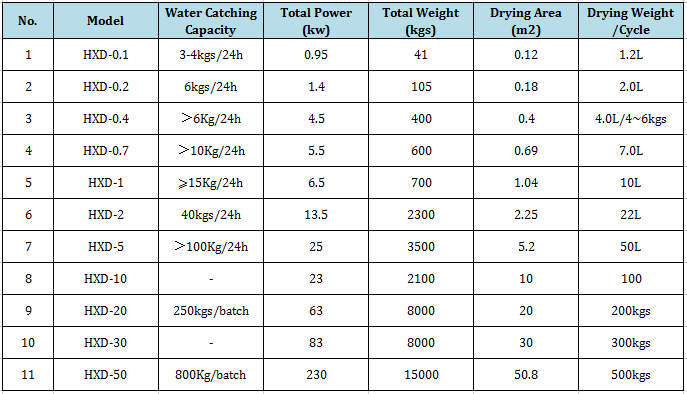

Model selection